Preventing Rubber to Substrate Bond Failures with the Right Adhesives

Reading Time: 5 minutes

Last Updated on February 24, 2025

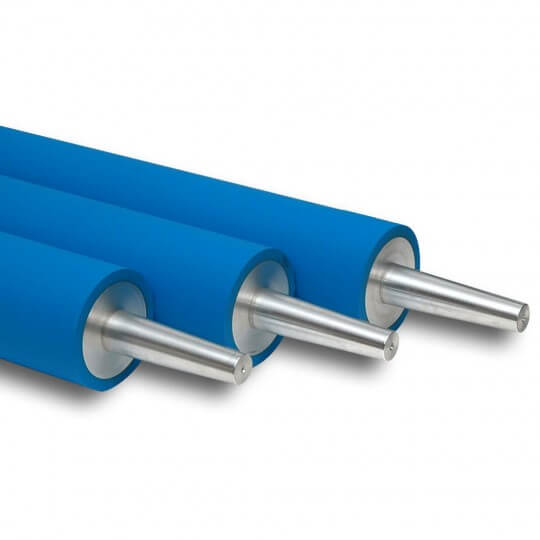

Rubber to substrate bonding refers to the process of combining elastomers to substrates made of various materials through various chemical and mechanical means. This bonding technique is utilized in numerous industries, including automotive, sealing, aerospace and many industrial applications where bond strength is key.

Applications for RTSB include automotive bushings, antivibration mounts, seals and gaskets, rubber and polyurethane wheels, rollers, belts and hoses.

Photo credits: linquip.com and joopstoop.com

Failure in the bonding process can result in costly failures in the end-use application. Bond failures can occur due to factors such as incompatible materials, improper storage, and issues during processing, like inadequate mixing, drying time and film thickness of coating.

H.M. Royal, a chemical product distributor experienced in this field, has extensively analyzed numerous potential causes of rubber to substrate bond failures. To prevent such failures, they recommend implementing the following measures.

Choose the Right Adhesive System

Rubber to substrate bonds are only as strong as the adhesives that keep them together. Without the right adhesive system, bond failures can occur, compromising the overall strength and durability of the assembly.

The Impact of Incompatibility

One common cause of bond failures is the incompatibility of adhesive agents. Adhesive compatibility between the polymer and substrate being bonded, as well as compatibility between adhesive systems (primer and top coat, for example), is critical to maintain bond both initially and long-term.

To avoid this cause of bond failure, it is essential to prioritize material selection and compatibility. This step can significantly minimize the risk of bond failures and ensure a strong and reliable rubber to substrate bond.

The Role of Adhesive Selection

Selecting the appropriate adhesive for the materials in question, as well as for the end-use environment of the part is absolutely critical. Let’s consider two solvent-based adhesives as examples:

- THIXON 2001-EF: This adhesive is specifically designed to bond natural rubber, chloroprene, butyl, SBR, EPDM, and nitrile to various substrates. It is formulated to provide adequate bond for these materials as well as resistance to typical environments where these materials are used.

- THIXON 405: On the other hand, THIXON 405 is formulated for bonding castable, millable, and thermoplastic urethanes to metal substrates, including various grades of steel, aluminum, and more. It offers excellent adhesion properties tailored for these specific combinations.

While both adhesives are solvent-based, it is important to understand that they perform optimally for distinct applications and substrates. By carefully considering the different adhesive options available and their recommended applications for rubber to substrate bonding, you can choose the adhesive system that best meets your needs and ensures a strong bond.

Embracing Sustainability

In today’s world, sustainability is a growing concern for many companies. If you are looking to produce environmentally-conscious products, selecting a different adhesive can make a significant impact. Certain adhesives eliminate raw materials of concern, contain lower VOC and HAP solvents, and have different levels of flammability.

Our material experts understand the importance of sustainability and can guide you in recommending compatible materials and application-specific adhesives for your needs. By choosing the right adhesive system, you can achieve both strong bonds and a positive environmental impact.

Understand the Rubber/Adhesive Relationship

Because bonded systems can fail for a number of reasons, it’s essential to understand the many causes and types of failure that can happen. From an adhesive standpoint, the ideal condition for bond failure is a rubber tearing or rubber retaining bond failure, where the adhesive system is adhered to both polymer and substrate.

A second type of common failure is called cement to metal/substrate failure (CM) substrate failure, where the bonding system does not achieve adhesion at the substrate surface, usually due to improper surface preparation.

Finally, rubber to cover (RC) failure is when the bonding system fails to achieve any adhesion with the polymer in question; the cause of which might be an adhesive that is unsuitable for the application, troublesome raw materials in the rubber formula, or even curing conditions.

By gaining a deep understanding of these factors, you can select an adhesive system that balances strength and flexibility, reducing the likelihood of failures and ensuring the longevity of the bond.

Surface Preparation: A Critical Step

In addition to the compatibility issues between adhesive agents and rubber, bonds may fail if the adhesive system doesn’t effectively bond the polymer to all coated areas. Contamination, such as oil, dust, or mold release agents, can form a barrier on the substrate surface, preventing proper adhesion.

To overcome this challenge, thorough surface preparation is essential. Ensure all components are clean, and surfaces are free from contaminants. Effective degreasing and removal of loose dirt or other substances are crucial steps in achieving a successful bond. Proper surface preparation minimizes the presence of contaminants that could interfere with the bonding process. Additionally, further surface preparation such as blasting, phosphatization, and other chemical and mechanical surface treatments can be advantageous to bond performance.

Proper Storage of Adhesives

Improper storage of unopened containers of adhesive agents can have a detrimental impact on bond integrity. Extreme temperatures, whether too high or too low, can result in degradation of the adhesive before application. This degradation reduces the effectiveness of cross-linking agents, making it difficult for the adhesive to bond to the rubber and can also make the adhesive unsuitable for brush, dip or spray, as the material will become too viscous to use.

To maximize the shelf life and effectiveness of adhesives, it is crucial to follow the storage instructions provided by the manufacturer. Adhering to the recommended storage temperatures ensures that the adhesive retains its optimal properties for bonding.

Adhering to Processing Directions

Deviation from the specified processing instructions can significantly impact the quality of rubber to substrate bonding. For example, the adhesive and rubber should have cure windows that overlap, neither curing too quickly or slowly to cross link with the other. Because heat and pressure are required for curing, it is essential to ensure that coated inserts are exposed to this heat and pressure within these parameters. Exposing coated inserts to mold cure temperatures for an extended period before introducing the rubber can lead to bonding failures as a result of what we call prebake.

Additionally, improperly mixed adhesives may contain settled solids that can compromise the integrity of the bond. Those critical bonding solids are left behind in the drum rather than applied to the part. Also related to mixing/solids distribution, over-dilution of the material can likewise weaken the reactivity of the system.

By adhering strictly to processing instructions, you can ensure that the bonding process occurs optimally, maximizing the strength and reliability of the rubber to substrate bonding.

Photo credit: Instron.com

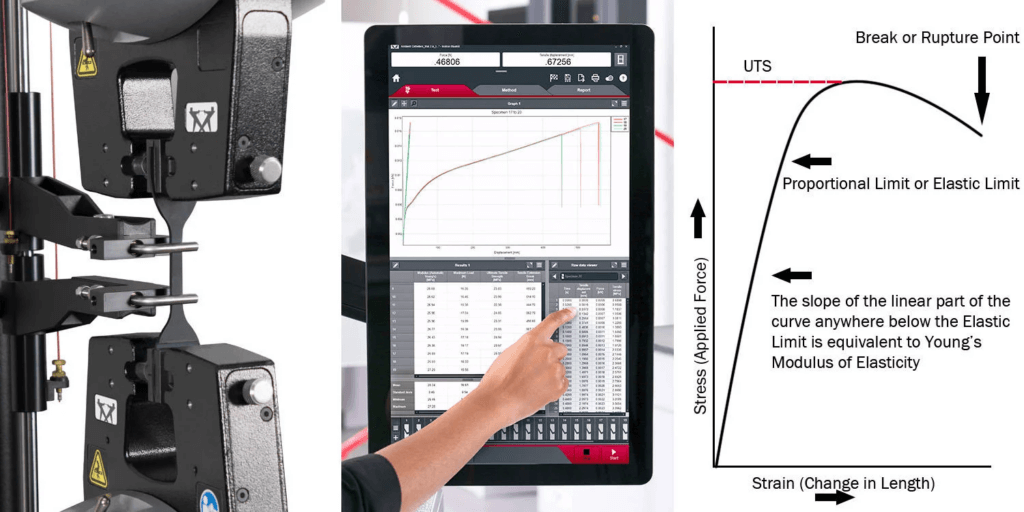

Testing for Bond Integrity

While following the aforementioned recommendations can greatly enhance bond strength, the only definitive way to verify the integrity and reliability of a bond is through testing. Destructive testing techniques can provide valuable insights into the quality of the bond and help identify any potential weaknesses.

If you encounter bonding failures or need assistance in preventing them, the experts at H.M. Royal are here to help. Contact us for a technical consultation, and our team will work with you to determine the source of the bonding failures and provide effective solutions.

Achieving strong rubber to substrate bonds requires a comprehensive approach that encompasses selection of the right adhesive system, material compatibility, proper surface preparation, storage, adherence to processing directions, and thorough testing. By carefully considering these factors and seeking expert guidance when needed, you can ensure durable and reliable bonds for your applications.

With the assistance of our material experts, you can ensure successful and reliable rubber to substrate bonds for your applications. Contact us for a technical consult.

For more information about bonding failures, download the infographic on Identifying a Rubber to Substrate Bond Failure below.

You can also email us at in**@*****al.com. Find out more about the products we represent at www.hmroyal.com.