Superconductive Carbon Black Additive Achieves the Highest Electrical Conductivity at the Lowest Concentrations

Reading Time: 3 minutes

Last Updated on February 17, 2025

Conductive carbon black is a popular performance additive that boosts the conductivity and mechanical properties of polymers, elastomers, and rubber compounds. Materials such as adhesives, plastics, and coatings often have low electrical conductivity, which limits their application in industries like electronics, automotive, medical, and aircraft where these properties are essential.

By incorporating conductive carbon black additives to reinforce material formulations, the final product can exhibit improved resilience, strength and conductivity. For example, in rubber compound formulations, carbon black additives are utilized to improve the electrical conductivity of tires. This enhancement helps dissipate static electric charges in tires, protects electronic circuitry and prevents sparks during refueling.

Conductive carbon black additives

Conductive carbon black is a specialized variant that offers higher electrical conductivity. Consisting of 99% amorphous carbon, its unique structure and the porosity of its crystalline particles contribute to its electrical conductivity. Various brands of conductive carbon black are available, each tailored for specific applications.

Lower concentrations with more conductivity

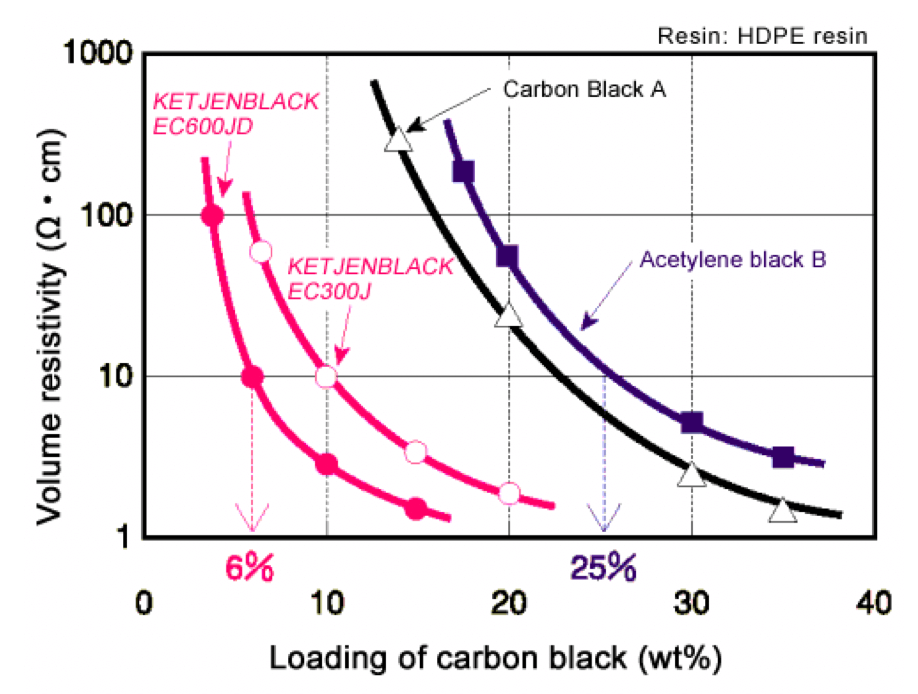

A superconductive carbon black produced by Nouryon called Ketjenblack achieves the same conductivity as conventional carbon blacks at substantially lower concentrations.

As the cost of carbon black oil, a primary element of carbon black, continues to rise, using lower concentrations reduces production costs. Depending on the grade, just one-third of the amount of Ketjenblack can achieve the same conductivity as other carbon black additives (see comparison graphic).

Photo credit: Lion Specialty Chemicals Company

Reduced Product Impact

Using lower concentrations of Ketjenblack can also decrease the overall load by up to half while maintaining the same conductivity levels as conventional carbon black. This reduced loading quantity minimizes the impact on final products, lessening effects on processing and mechanical properties (results vary by application as the loading required to achieve a particular conductivity can differ based on the polymer.)

Ketjenblack carbon achieves the same resistivity as a competitive carbon black with 1/2 to 2/3 of the loading quantity. Source: KETJENBLACK Highly Electro-Conductive Carbon Black | Lion Specialty Chemicals Co., Ltd. (lion-specialty-chem.co.jp)

Different Grades

Ketjenblack is available in two grades to meet the requirements of specific applications.

- EC-300J is very pure and compatible with all polymers, resins, coating, and inks. Its very low ash content makes it a preferred choice in cable shielding and producing conductive coatings.

- EC-600JD is a top-end superconductive black carbon with very high purity compatible with all polymers, batteries, and fuel cells. Only one-third of EC-3000J is needed to replace conventional electroconductive blacks. About 40% less is needed of EC-600JD compared to EC300J.

Below is a comparison of the two grades.

Applications

Ketjenblack can be added to resin compounds, polymers, thermosets, thermoplastics, and elastomers to create electro-conductive battery materials, paint, colorant, and toner in the protective packaging of electronics, fuel tanks and hoses, conductive flooring, high-voltage cables, batteries, fuel cells, and conductive paint.

As a leading raw materials and specialty chemicals distributor, H.M. Royal is a trusted provider of conductive carbon black additives from Nouryon. Contact a raw materials specialist who can answer your questions and choose the grade and quantity of KetjenBlack for your application. You can also email us at in**@*****al.com. Co