Platinum Cured Silicone: How Platinum Curing Expands the Use of Silicone Rubbers

Reading Time: 4 minutes

Platinum-cured silicone is being used for more applications today than ever before. The inherent physical properties of silicone rubber, such as its resistance to water and heat, make it suitable for a variety of products. While peroxide has been the industry standard for curing these products for many years, platinum curing is emerging as a purer process that produces stronger and more esthetically pleasing products.

Uses of silicone rubber

Silicone rubber is a synthetic elastomer possessing a range of inherent physical properties that distinguishes it from other elastomers. It’s known for its excellent mechanical attributes, high resistance to temperature and flames, its ability to repel water, and its high transparency. These qualities make it a top choice for countless applications such as:

- Gaskets and seals for the automotive industry

- Seals, tubes and valves for instruments in the healthcare industry

- Molded and extruded articles that require good transparency

Many industrial applications require silicone in a solid form in their injection molding extrusion, compression molding and other processes. The solid form of silicone rubber, also known as high consistency rubber (HCR), contains polymers with a high molecular weight and long polymer chains. HCR needs to be vulcanized.

There are different methods to vulcanize (cure) silicone rubber, but the most used are peroxide crosslinking and platinum-catalyzed addition curing. As the curing agents vary chemically, end products differ slightly in properties.

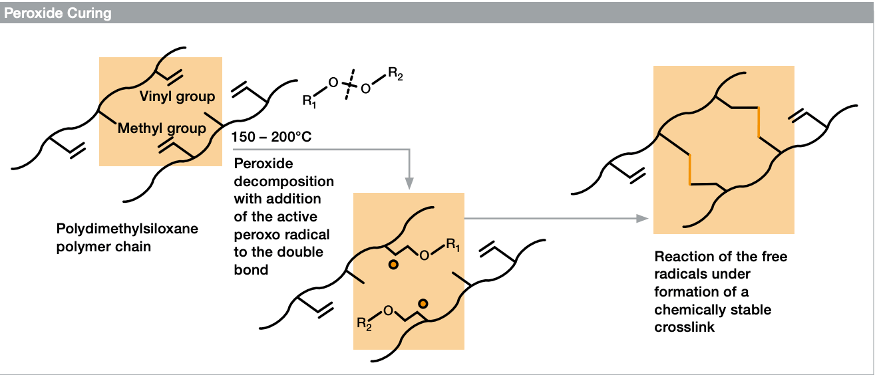

Peroxide Curing

Peroxide curing is a well-established free radical curing process that uses organic peroxide at elevated temperatures to cure the rubber. It works by chemically crosslinking different polymer chains to form a resilient, three-dimensional lattice. This method is straightforward, and there are processing benefits. The uncured material has an extended shelf life, and it is not susceptible to catalyst poisons.

Silicone rubber cured by peroxide can be processed using standard methods such as extrusion, compression, transfer molding, calendering, and injection molding. Because of its strength and durability, peroxide-cured silicone rubber is ideal for mechanical rubber goods.

However, there are certain limitations to peroxide curing. This process can leave residuals, limiting its use in food-grade and medical uses.

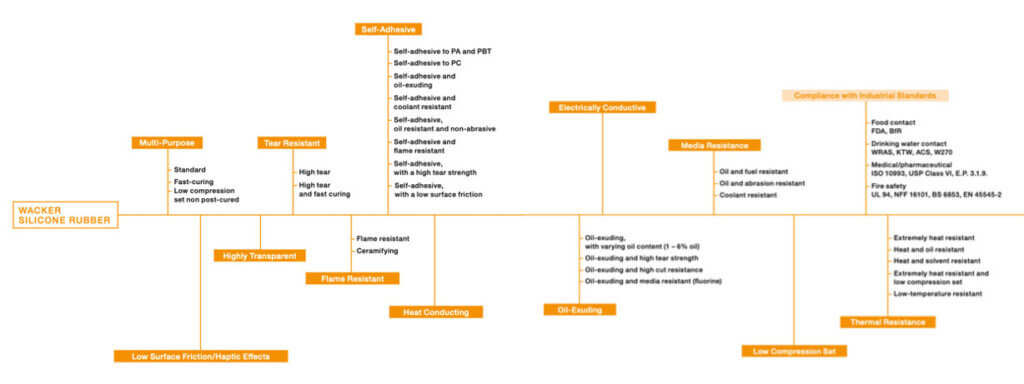

Grades of Peroxide-Cured Silicone Rubber

Peroxide-cured silicone rubber is offered in different grades with varying characteristics to address the requirements of specific applications.

These include:

- High strength

- High heat resistance

- Low-temperature resistance

- Electrical conductivity or insulation

- Tear resistance

WACKER offers a range of peroxide-cured HCR grades marketed as ELASTOSIL® R.

- The ELASTOSIL R-401 series are general-purpose-grade silicones featuring good flexibility, high transparency and good mechanical properties. They are typically used for producing molded, extruded or calendered articles like seals, gaskets, sheets, tubing, and profiles for automotive parts, ignition and battery cables as well as cables for household appliances.

- The ELASTOSIL R 420 & 427 series of products expands on the characteristics of the R-401 series to include high tear resistance and high transparency. The elastomer also is used in producing molded, extruded, or calendered items, but with high tear resistance. Applications include molded parts, profiles and vibration damping.

Other grades offer low compression set, high rebound resilience and high heat resistance. For instance, the ELASTOSIL R-770/75 is a peroxide-cured HCR silicone intended for the manufacture of flame-retardant products.

The Platinum Curing Difference

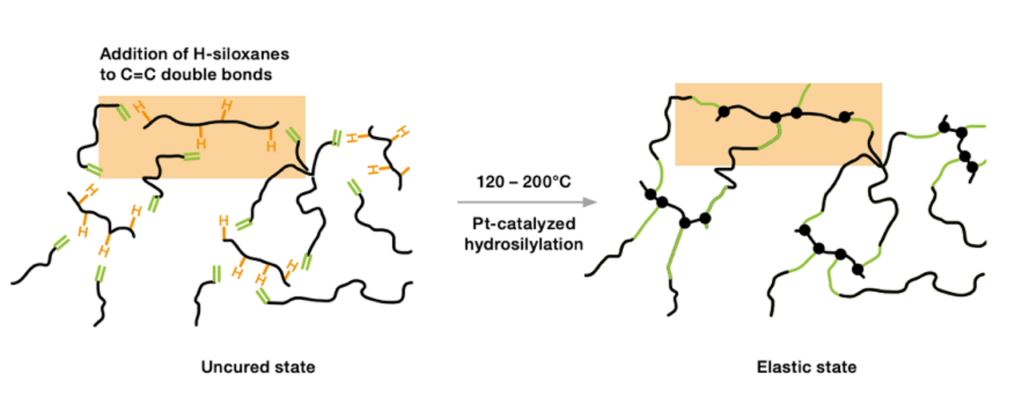

Platinum-curing of silicone, also referred to as the “addition-curing” method for silicone rubber, is a relatively recent development. In this process, platinum is introduced to serve as a catalyst, initiating a reaction between the Si-H groups of crosslinkers and the vinyl groups of polymers to generate a three-dimensional structure.

One of the biggest advantages of the platinum curing process is its purity. Unlike peroxide, it doesn’t produce any residuals or byproducts, preventing mold contamination and hence, improving productivity. The curing process is fast, with the rate controlled by temperature.

Furthermore, platinum-catalyzed addition reactions do not produce odor- or flavor-impairing byproducts, which is crucial for food and beverage products. Because it does not release volatile byproducts, platinum-cured silicone is often preferred for healthcare and FDA applications such as pharmaceutical and medical technology tubing and well seals, valves, filters and membranes for respiratory equipment.

In terms of aesthetics, platinum-cured silicone rubber is visibly clearer and doesn’t discolor after curing. On the contrary, peroxide-cured HCR has a slightly hazy appearance, which can obstruct visual inspections of tubing. Lastly, products made with platinum-cured silicone rubber have superior tensile and tear strength compared to those made with peroxide-cured materials.

Grades of Platinum Cured Silicone

WACKER offers a range of platinum cured silicone grades marketed as ELASTOSIL® R plus 4305. They are addition-curing, two-component high consistency silicone rubber used to manufacture molded or extruded parts. Cured parts have excellent transparency and good mechanical properties. This silicone is ideal for baby care, dairy and food applications, profiles and tubing, and sanitary products. When properly post-cured, these vulcanizates comply with BfR and FDA food contact regulations.

The platinum catalyst is added later in the mixing process. Depending upon the processing method, the formulator can select either the AUX PT 1 or AUX PT 2 catalyst.

- The AUX PT 1 catalyst is faster curing and is typically used in the extrusion process where line speed and dimensional stability are critical. The dosage of AUX PT1 is approximately 1.5 phr.

- The AUX PT 2 catalyst is slower curing and is used in molded applications. The slower cure time allows the uncured rubber to flow and fill the entire mold cavity before curing. Catalyst AUX PT2 is also added at 1.5 phr.

Read more about the solid silicone rubber offered by WACKER at Solid silicone rubber (HTV) – Wacker Chemie AG (link) or contact H.M. Royal at (800) 826-8175 to discuss your application and to find the right HCR to meet your specifications.