Ensuring the Safety and Effectiveness of Medical Devices with Wacker SILPURAN Silicone Rubber

Reading Time: 3 minutes

Last Updated on February 27, 2025

With the average age of the population increasing steadily, manufacturers are finding it difficult to keep up with the rising demand for medical devices. In response to the ever-increasing demand, Wacker developed its SILPURAN® product line. SILPURAN silicone elastomers are reliable, safe, incredibly resistant to heat and radiation, and meet high safety standards for medical applications.

Suitable for use in extrusion, compression and injection molding, SILPURAN medical-grade silicone rubber compounds have excellent mechanical properties, are very durable, and serve as good elastic sealing materials. They have become a popular option for numerous pharmaceutical and medical technology/tubing applications.

Keep reading to learn why SILPURAN rubber compounds are ideal for a wide variety of demanding medical applications.

Benefits for Medical Technology

SILPURAN products are available in a variety of hardnesses (Shore A) to meet medical technology needs. The SILPURAN products are biocompatible in accordance with UPS Class VI and selected tests of ISO 10993: Cytotoxicity, Sensitization Pyrogenicity, Systemic Toxicity, Intracutaneous toxicity and Implantation (120h).

They have good resistance to UV radiation and X-rays for sterilization. In addition, they provide excellent heat resistance as well as chemical and physical resistance with no additional stabilizers. Their high transparency means that they do not restrict the coloring possibilities for your medical products in any way.

The SILPURAN product line offers unique benefits for a wide range of medical applications, including:

- Tubing connectors

- Ventilation masks

- Respirators and respiratory bellows

- Handles for surgical instruments

- Breathing tubes

- Seals for disposable syringes

- Mats for sterilization trays

Resistance in Standard Sterilization Procedures

It is important to rule out any potential hygienic hazards during the manufacturing process for medical technology. To ensure product safety and prevent medical device shortages, manufacturers use various sterilization procedures. The most common sterilization methods for medical applications are dry heat/steam, chemical substances such as ethylene oxide, or radiation. Single-use articles are typically sterilized in their packaging using radiation or ethylene oxide.

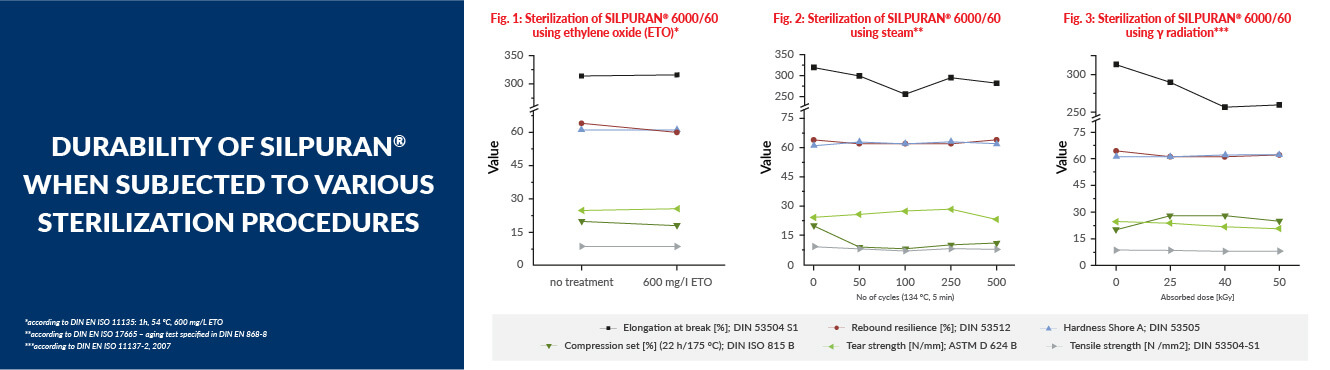

Different sterilization methods can affect the mechanical properties of medical devices. SILPURAN products, however, can withstand various types of sterilization with no effects on mechanical properties. Mechanical properties are not influenced by ethylene-oxide sterilization, as shown in Figure 1. Very slight changes occur during steam sterilization at 134 ℃ and up to 500 cycles (Figure 2).

Using radiation for sterilization may result in changes to the polymer network. Tests have shown that sterilization using γ / β radiation can make soft materials (5 to 50 Shore A) moderately more brittle and influence other mechanical properties as well. Only minor changes occur with harder materials, as shown in Figure 3. However, application specifications are usually not compromised and the functionality of the end product remains intact.

Ultra-High Purity

Silicones used in medical devices come into direct contact with the human body and, therefore, must meet the stringent demands of the healthcare industry. The WACKER CLEAN OPERATIONS program ensures that all SILPURAN products meet today’s ever-increasing safety requirements. This means we can verify purity, tracing it from the end product back to the raw material source.

SILPURAN contains only precisely defined ingredients, such as siloxanes, silica, curing agents, and catalysts. No organic plasticizers are added. Additionally, all products are dispensed and packaged in cleanrooms to prevent contamination from coarse particles. Visual inspection and 50 μm filters ensure that silicone products reach end-users in a clean and pure state.

H.M. Royal offers a variety of SILPURAN and ELASTOSIL® medical-grade silicone rubber elastomers for a range of molding applications. Products are available as solid (HCR) or liquid silicone rubber (LSR) and as room temperature vulcanizing products (RTV-2).

For more information or help selecting the best product for your application, contact an H.M. Royal expert today.