Dualite Microspheres Offer Exciting New Opportunities for Product Weight Reduction

Reading Time: 2 minutes

Last Updated on May 17, 2019

Manufacturers are always looking for ways to reduce the weight of their products, especially if they sell on a volume basis. A reduction in weight can contribute to savings or allow extra weight for additional materials.

Newer technologies like microspheres allow for a lighter weight product without sacrificing performance or reliability. Microspheres are microsphere lightweight fillers that can be created from synthetic and natural materials such as glass, ceramic and polymers. They can dramatically reduce the cost and weight of your formulas and products. Depending on the intended application, they can feature a hollow or solid structure.

Microspheres can be used in a variety of applications, including plastics, resins, adhesives and composites. They offer a number of benefits, ranging from lower density and improved insulation to more efficient machining.

Weight Reduction with Dualite® Microspheres

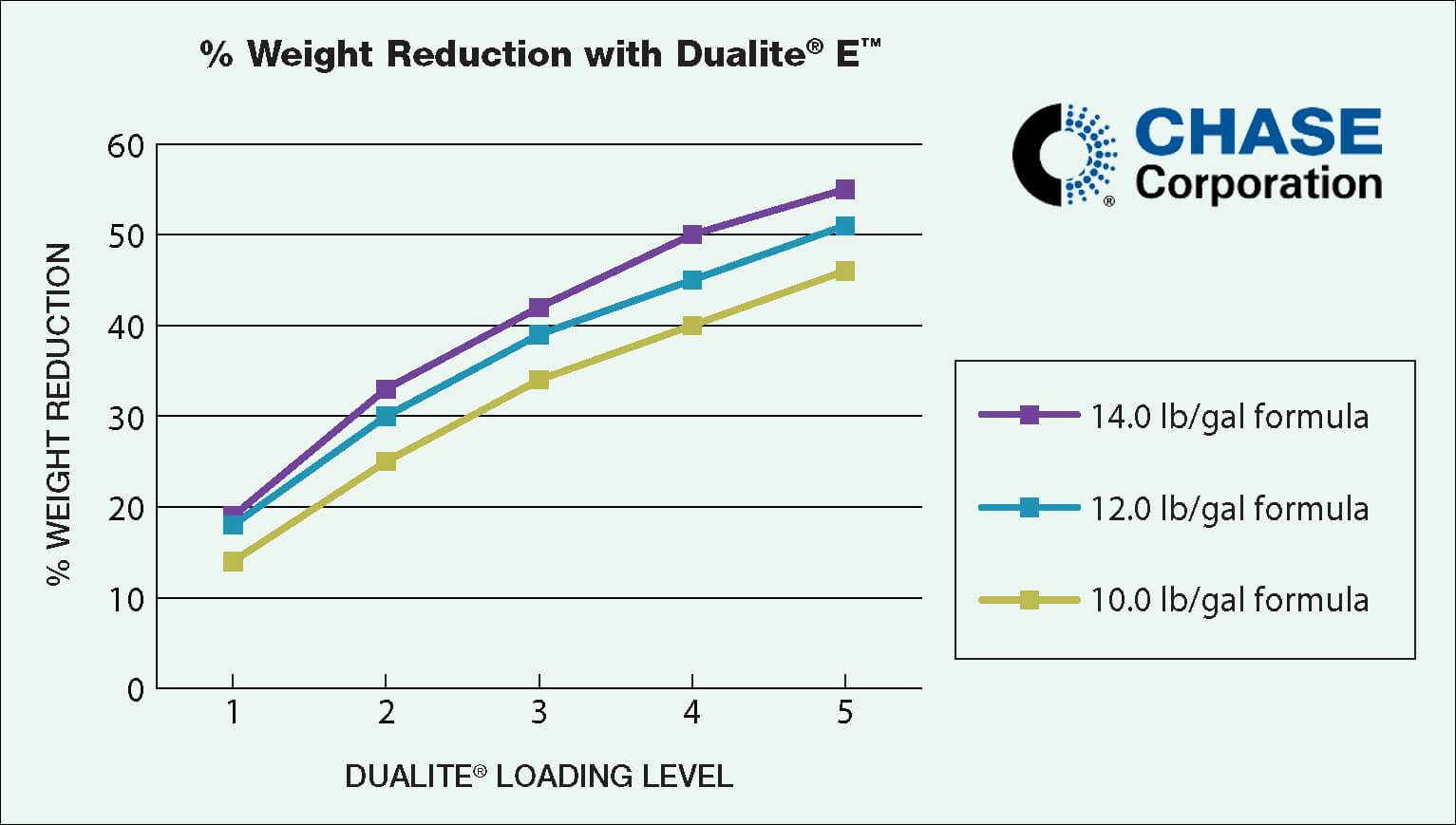

Using Dualite® microspheres from Chase Corporation can significantly reduce the weight of your products. Dualite microspheres offer extremely low density, making them an ideal replacement for higher density raw materials. By adding as little as 2-3% by weight, you can reduce your product’s weight by as much as 40-50%. This weight reduction can lead to easier handling, both internally and by your customers. It also offers other benefits like freight savings and reduced product “slump” on vertical surfaces.

Dualite® microspheres reduce weight while increasing your volume and lowering your cost by volume. Chase Corporation creates Dualite® microspheres using a patented process that controls expansion coating application. They are available in a range of particle sizes, densities and materials to meet the needs of numerous industries and end-use applications.

Dualite® microspheres can be used as a lightweight filler in many applications, including paints, coatings, adhesives and sealants. They are an ideal option for manufacturers who sell on a volume basis.

The chart below shows the percent weight reduction for formulas with initial specific gravities of 10, 12 and 14 pounds/gallon. This was calculated at different loading levels of Dualite® E™ 065-135D.

Additional Benefits of Using Microspheres

In addition to weight reduction, Dualite® microspheres can help improve the surface quality of your products. Because microspheres are ultra-lightweight, they migrate towards the part’s surface, resulting in a smoother exterior on the finished part. Microspheres can also absorb energy/impact, protecting your parts from cracking or breaking.

There are many different types of microspheres to consider when choosing a low-density filler for your applications. The challenge is finding the right microsphere for your application.

At H.M. Royal, we are a trusted supplier of Dualite® microspheres as well as a variety of other performance additives including aramid fibers and odorants. If you are looking for a microsphere or low-density filler blend, our team of experts can help you determine the best choice for your application needs.