The Unlikely Pairing of Chem-Trend Release Agents and DuPont RTSB Adhesives

Reading Time: 3 minutes

Last Updated on August 12, 2025

Sometimes, the most unlikely combination of seemingly dissimilar chemical ingredients can work together to produce truly amazing results. One standout example is the unexpected yet effective synergy between Chem-Trend release agents and DuPont rubber-to-substrate bonding (RTSB) adhesives.

At first glance, these products serve opposite purposes. Release agents are designed to prevent materials from sticking to molds, while adhesives are formulated to create strong, lasting bonds. However, these two products work together seamlessly to ensure consistency, quality and reliable performance in molded rubber components. Here’s how.

Why Mold Release Agents and RTS Adhesives Work Together

In the rubber molding process, rubber is shaped under heat and pressure in metal molds. In many cases, it is essential for the rubber to be fully released from the metal mold without causing surface damage or contamination.

Chem-Trend release agents facilitate easy part removal without leaving residue or damaging the mold, preserving mold integrity and surface finish. They work without interfering with the bonding process—a common issue with less specialized release agents.

DuPont RTSB adhesives create durable, high-performance bonds between rubber and metal. Their advanced formulations ensure strong adhesion even under extreme temperatures and stress.

When used together, these products streamline production, reduce scrap, and maximize bond integrity, helping our customers achieve efficient, consistent molding.

DuPont RTSB Adhesives Improve Rubber Molding

DuPont offers rubber to substrate bonding adhesives for countless applications. Bonding rubber to various metals and plastics requires a custom-formulated adhesive system that provides strong, reliable and durable adhesion. To meet varying demands, DuPont has several types of RTSB adhesives:

- MEGUM™: Ideal for bonding polymers to metal.

- THIXON™: A versatile adhesive suitable for a wide range of substrates.

The One-Coat Bonding Advantage with THIXON and MEGUM

Traditional bonding systems typically require two coats: a primer followed by a topcoat adhesive. THIXON and MEGUM one-coat adhesives eliminate this extra step, simplifying operations without compromising strength or durability. Benefits include:

Faster processing

A two-coat system requires waiting between the primer and topcoat applications. A one-coat formulation can be applied directly to metal, needing only one drying cycle before molding.

Reduced equipment needs

Two-coat systems require separate spraying equipment for each coat or extensive cleaning between each coating. A one-coat system requires only one dip tank or spray system, simplifying application and reducing contamination risks.

Strong, reliable bonds

The single layer provides excellent adhesion and environmental resistance.

Simplified supply

Reducing the need for two coatings down to just one translates into savings in logistics and storage capacity.

Lower solvent use

When diluting adhesives for application (especially spray), a diluent is needed for both the primer and the top coat. Primers and top coats usually involve different solvent systems (primers often use MIBK or MEK while topcoats typically use Xylene or Toluene), so using one coat cuts down the number of solvents needed for dilution and cleanup.

Versatile performance

Compatible with a range of elastomers and substrates.

Potentially reduced adhesive usage

While the typical dry film thickness for a primer like THIXON P-6-EF is between 0.2 and 0.3 mils and a cover-coat like THIXON 532-A-EF is recommended at 0.8-1.0, a single-coat system like THIXON OSN-2-EF or MEGUM 15637 provides a total film thickness of 0.8-1.2 mils, which suits most applications.

One-Coat Simplifies Bond Failure Analysis

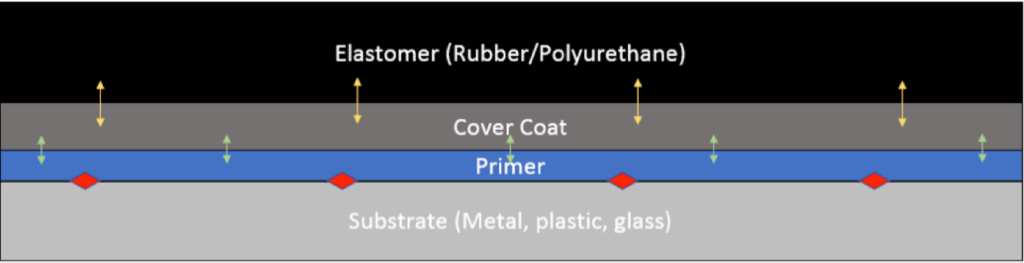

Bond failures are rare, but analyzing them is simpler with one-coat systems. In a two-coat system, like the depiction below, a potential bond failure can occur in three areas:

- Between the metal and the primer.

- Between the primer and the cover coat.

- Between the cover coat and the elastomer.

With one-coat adhesives, any adhesive failure occurs between the metal and the one-coat or the one-coat and the rubber, reducing potential failure points.

Download Free Infographic: How to Identify a Rubber to Substrate Bond Failure

Chem-Trend Mold Release Agents Expedite the Rubber Manufacturing Process

Chem-Trend Mono-Coats are semi-permanent mold release agents applied to metal molds to allow cured rubber parts to be released effortlessly, much like non-stick spray for baking. Key advantages for compounders:

Long-lasting release: One application can support multiple parts or cycles, reducing reapplication frequency and saving time and labor.

Uniform quality: Consistent film thickness and even coverage deliver defect-free finishes.

Eco-friendly: Low VOC and solvent-free formulations are available.

Application versatility: Available in silicone-based, non-silicone-based, and water-based versions for different rubber types and processes.

Your One-Stop Source for Bonding Solutions

By offering both DuPont RTSB adhesives and Chem-Trend Mono-Coat mold release agents, HM Royal provides a comprehensive solution for rubber-to-metal and rubber-to-plastic bonding processes. Customers benefit from:

- Simplified sourcing from a single distributor

- End-to-end product compatibility

- Coast-to-coast customer service

- Expert technical assistance, including in-house bonding evaluations and failure analysis.

As the exclusive U.S. distributor for these leading brands, H.M. Royal is your partner in solving rubber bonding challenges. Contact us today for technical data sheets or more information.