Dualite® Polymer Microspheres Offer Product Weight Reduction and Cost-Saving Opportunities

Reading Time: 4 minutes

Last Updated on January 7, 2026

Manufacturers are always looking for innovative ways to reduce product weight, especially for high-volume goods. Even small weight reductions contribute to significant cost savings. According to The American Society of Mechanical Engineers, a 10 percent reduction in weight lowers manufacturing costs by 4 percent.

Weight reductions can also improve environmental initiatives by reducing energy usage and overall carbon footprint. Weight reduction additionally provides greater design flexibility, enabling engineers to integrate new features or materials without exceeding weight constraints..

One of the most effective solutions for achieving meaningful weight reduction is the use of polymer microspheres. These lightweight, versatile fillers can be incorporated into product formulations without compromising performance or reliability.

Polymer microspheres can also reduce volatile organic compound (VOC) emissions and improve machining and processing characteristics depending on the application.

What are Polymer Microspheres?

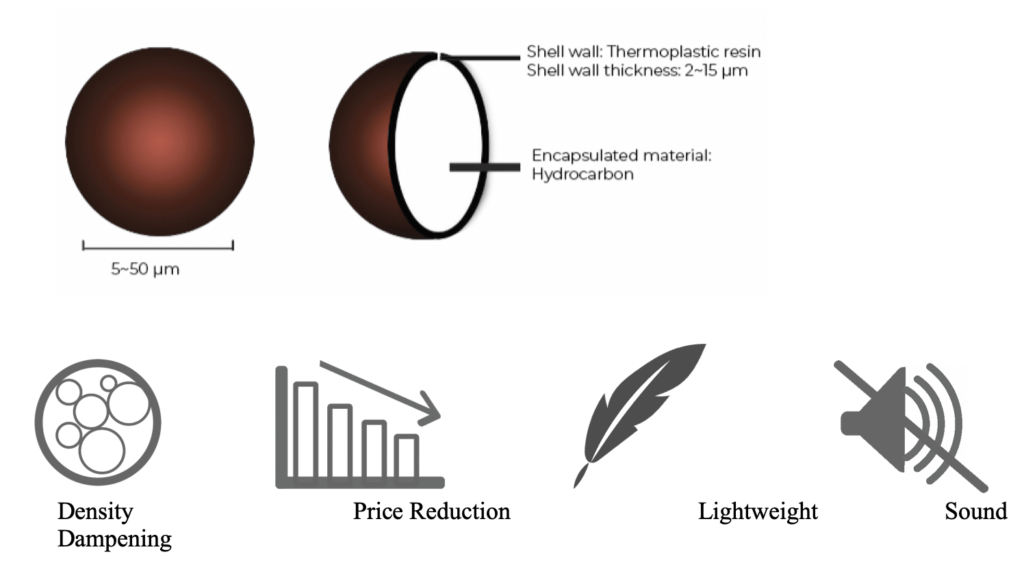

Polymer microspheres are lightweight, high-performance fillers available in a wide range of synthetic and natural materials, including glass, ceramic, and polymers. Their unique spherical geometry, either hollow or solid, allows formulators to dramatically reduce weight, density, and raw material cost without compromising performance.

Microspheres are used across numerous industries and applications, including plastics, resins, adhesives, sealants, and composite materials. In manufacturing environments, they can improve dimensional stability, reduce shrinkage, lower density, and enhance insulation for more efficient machining.

Specialized Dualite Microspheres

Dualite® microspheres from Chase Corporation are specialized polymer microspheres engineered using a patented process that precisely controls both expansion and coating application. Made from a flexible polymer shell, these ultra-lightweight fillers are available in a range of particle sizes, densities, and material compositions to meet the demands of diverse industries and applications, including paints, coatings, adhesives, and sealants.

Dualite polymer microspheres can be blended into plastics, resins, adhesives, and composite materials. They offer significant weight reduction, cost savings, density control, and improved environmental performance, making them an ideal choice for manufacturers whose products are sold by volume.

Dualite polymer microspheres are available in two forms:

- Unexpanded Microspheres – Solid spheres that expand during processing and serve as alternatives to traditional chemical blowing agents. These allow for in-process expansion, giving manufacturers control over final product density and performance.

- Pre-Expanded Microspheres – Already expanded and coated with fine mineral particles like calcium carbonate, these can be directly incorporated into formulations, simplifying processing while maintaining consistent low density and stability.

How Dualite Microspheres Reduce Weight

Incorporating Dualite microspheres into your product formula can result in substantial weight reduction. Due to their extremely low density, these microspheres volumetrically replace higher-density, more expensive raw materials—reducing costs while maintaining performance.

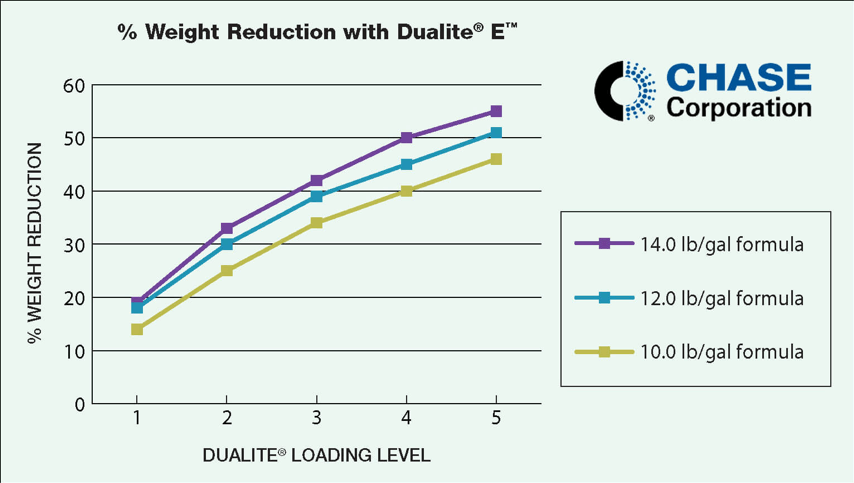

Adding as little as 2–3% by weight can reduce total product weight by as much as 40–50%, depending on the formulation. This weight reduction can lead to easier handling for both production teams and your customers. It also lowers freight savings due to decreased product weight and minimizes product sag or “slump” on vertical surfaces.

The chart below shows the percent weight reduction in formulas with initial specific gravities of 10, 12 and 14 pounds/gallon, based on varying loadings of Dualite® E™ 065-135D. It clearly demonstrates how even small additions of polymer microspheres can create significant reductions in overall product weight.

Environmental Benefits of Using Dualite Microspheres

In addition to their performance and cost advantages, Dualite® polymer microspheres deliver several meaningful environmental benefits, helping manufacturers create sustainable products:

- Lower VOCs – Reduce solvent migration, improving indoor air quality.

- Higher R-Value – Enhance thermal resistance for greater energy efficiency.

- Faster Drying – In water-based systems, increased volume reduces energy needed for drying.

- Improved Workplace Safety – Serve as safer alternatives to chemical blowing agents.

- Better Fuel Efficiency – Lighter coatings improve vehicle and equipment efficiency.

- Noise Reduction – Natural sound-dampening properties reduce vibration and noise.

- Material Efficiency – Allow reductions in base material without sacrificing strength or performance..

Improved Surface Quality

Dualite polymer microspheres can also improve surface appearance. Their lightweight spherical structure naturally migrates toward the surface during processing, creating a smoother, more uniform finish.

Additionally, they help absorb and distribute impact energy, increasing durability and resistance to cracking or breakage.

Calculate Savings With Polymer Microspheres

Dualite microspheres offer a cost-effective alternative to expensive resins and other high-density raw materials, while preserving key product properties. Beyond material substitution, they also contribute to reduced shipping costs and lower energy consumption due to their lightweight nature.

Example Volume Cost Calculation:

For a 12 lb/gallon formula costing $0.92/lb, the volume cost =

12 x $0.92 = $11/gallon

Chase Corporation provides a downloadable cost-saving calculator to help manufacturers assess potential savings when substituting raw materials with microspheres in adhesives, composites or resins.

Industries and Applications

With various grades available, Dualite microspheres can be tailored to meet the specific needs of diverse applications:

- Automotive & Transportation –Lightweight fillers for tires, underbodies, panels, and sound-dampening layers.

- Construction Products – Used in roof coatings, patching compounds, insulation foams, and cement adhesives.

- Textiles – Serve as fillers in paints and coatings, reducing pigment usage.

- Packaging – Improve durability, processability, and cost-efficiency in sealants and adhesives.

- Aerospace – Enable lighter composites for improved fuel efficiency and performance.

- Marine – Enhance coatings and composites used in hulls, interiors, and marine structures, with durability and reduced environmental wear.

Ready to replace your raw materials with Dualite?

Chase Chase Corporation offers multiple grades of Dualite polymer microspheres, each engineered for specific densities, particle sizes, and coating types to meet a range of application requirements.

H.M. Royal is a trusted supplier of Dualite polymer microspheres and other performance additives including aramid fibers and odorants. Our experts can help you determine the best microsphere or low-density filler blend for your formulation needs.

Email us at in**@*****al.com or refer to www.hmroyal.com to find out more about the products we represent.