Calculate Your Savings Using Dualite® Polymer Microspheres In Place of Expensive Raw Materials

Reading Time: 3 minutes

Chase Corporation now offers a cost-saving calculator to evaluate your application savings when replacing expensive raw materials with Dualite® microspheres in resin, adhesive and composite compounds. In addition to reducing costs, these microscopic and ultra-lightweight fillers can lower density, improve insulation, reduce VOCs, and improve machining, depending on the application. They also enable the production of a lighter-weight product without compromising performance and reliability.

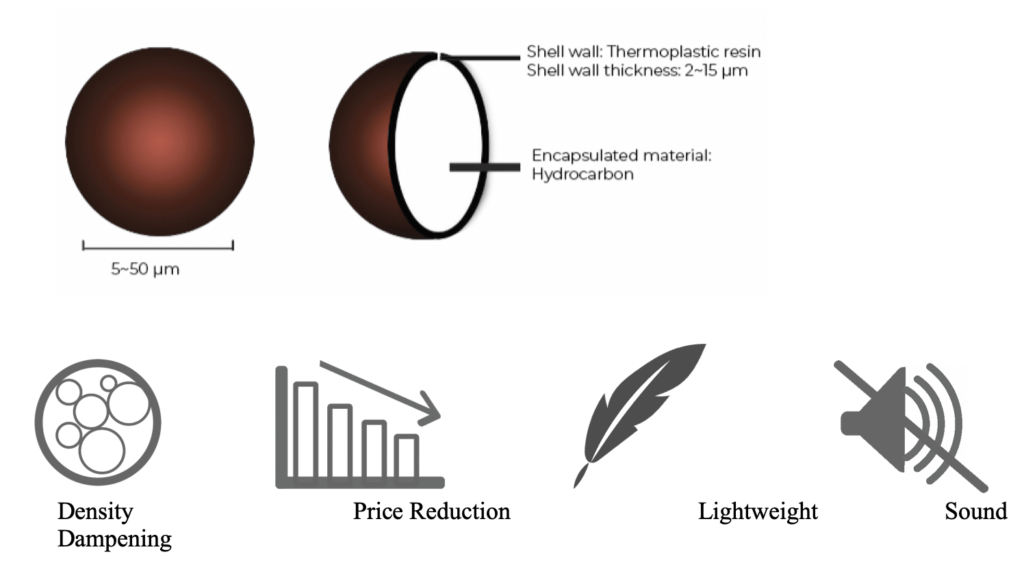

Created through a patented process that controls expansion and coating application, Dualite polymer microspheres are lightweight and available in a range of particle sizes, densities, and materials for use in a broad spectrum of end-user applications.

Dualite Microspheres are ultra-lightweight fillers made from a flexible polymer shell.

Environmental Benefits of Dualite Lightweight Microsphere Fillers

- Reduced Weight: Using less of this raw material reduces product weight. Adding 1% to 3% of Dualite can reduce weight by 15 to 20%. Weight reduction can result in cost savings or allow extra weight for additional materials. They are ideal for manufacturers who sell on a volumetric basis.

- VOCs: As more emphasis is placed on sustainability and green initiatives in manufacturing, these polymer microspheres impede solvent migration during the mixing/manufacturing process.

- Increased R-value: Increases the thermal resistance of the end product.

- Less Energy: Water-based systems dry faster since Dualite takes more space in the mix.

- Safer Workplace: Unexpanded microspheres replace chemical blowing agents that can pose a threat to both workers and the environment.

- Improved fuel efficiency: By making sealants and coatings lighter, Dualite products improve vehicle fuel efficiency.

- Sound dampening: Reduces vibration and sound emission to reduce noise pollution.

- Impact and crack resistance: Extends the life of end products.

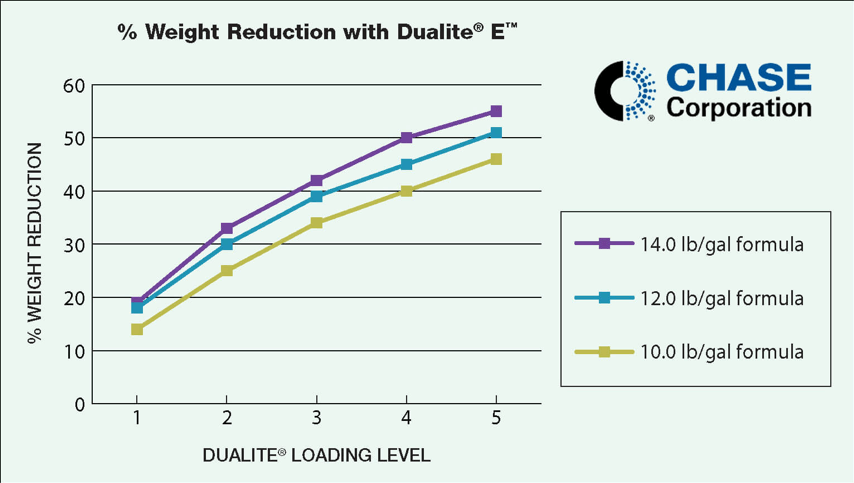

This chart shows the percent weight reduction for formulas with initial specific gravities of 10, 12, and 14 pounds/gallon. This was calculated at different loading levels of Dualite® E™ 065-135D.

Cost Savings You Can Calculate Now

Reduced product weight and lower volume costs make Dualite Microspheres a more attractive alternative to more costly resins while maintaining end-product properties. In addition to replacing expensive raw materials, Dualite reduces shipping expenses and energy consumption. To evaluate your application costs, download the Cost Savings Calculator Tool.

Range of Applications

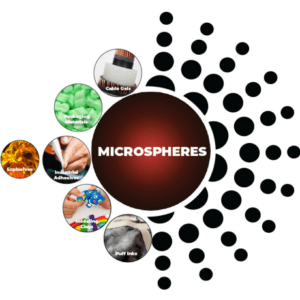

The different grades of Dualite Microspheres offer unique solutions for a variety of end uses including plastics, cable gels, packaging materials, modeling clay, coatings, and adhesives. Industries that can benefit from this ultra-lightweight resin include:

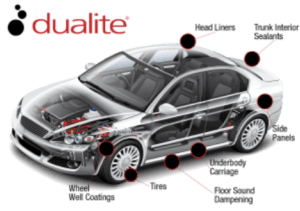

- Automotive & Transportation (tires, side panels, underbody carriage, wheel well coatings, floor sound dampening)

- Construction Products (cement adhesives, roof coatings, sealants, patching compounds, insulation spray foams, and more)

- Textiles (paints and coatings)

- Packaging (adhesives and sealants)

- Aerospace

- Marine

- Energy

Interested in replacing your raw materials with Dualite? We can help you choose the right microsphere for your application. H.M. Royal is a trusted supplier of Dualite microspheres and other performance additives including aramid fibers and odorants.

If you are looking for a microsphere or low-density filler blend, our team of experts can help you determine the best choice for your application needs. You can also email us at info@hmroyal.com. Find out more about the products we represent at www.hmroyal.com.

(800) 257-9452

(800) 257-9452